Understanding Dry Ice

Decoding the Nature of Dry Ice

Dry ice is an intriguing substance, often shrouded in mystery due to its unique properties and bewildering effects. It is the solid form of carbon dioxide, transforming from solid to gas without passing through a liquid state, a process known in chemistry as sublimation. Unlike regular ice, typically made from frozen water, dry ice serves a variety of purposes beyond just chilling your drinks.

At standard atmospheric pressure, the low temperature of dry ice (-78.5°C or -109.3°F) makes it extremely cold, which can be beneficial in various industrial applications and food preservation. However, handling dry ice requires caution due to its potential hazards if not managed properly.

When dry ice sublimates, it turns into carbon dioxide gas, which can create the iconic fog effect famously used in entertainment venues and on stage to conjure an ambiance of mystery and magic. But it’s not just for show. This same property is effectively utilized in industries such as ice blasting for cleaning surfaces by displacing dirt and debris through high pressure, without leaving any residue.

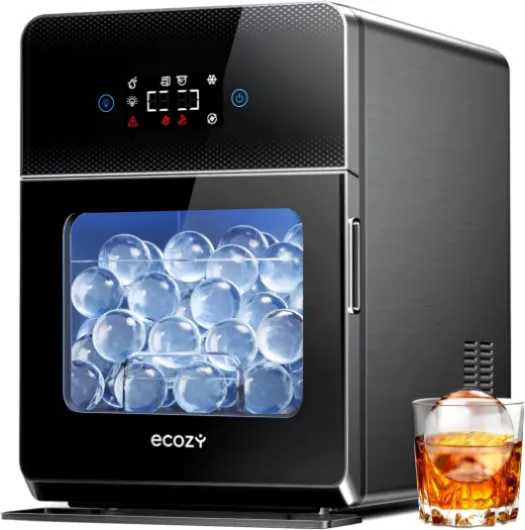

Furthermore, anyone interested in diving deeper into the captivating world of dry ice can also explore how it enhances the magic of crystal clear ice cubes in cocktail presentations, offering both visual appeal and functionality.

Industrial Applications of Dry Ice

Revolutionizing Cooling Processes

In the industrial landscape, dry ice proves to be an invaluable resource due to its unique properties and adaptability across various applications. Comprising solid carbon dioxide, dry ice offers a cold, non-liquid option for industries needing temperature control solutions. When ice used as an alternative to regular ice, dry ice does not melt into a liquid, instead sublimating into a gas. This allows for a consistent cold temperature environment, crucial for preserving perishable goods and materials vulnerable to heat.

Enhancing Food Storage and Transport

One prominent use of dry ice is in the food industry, especially for transportation and storage. Capable of maintaining a consistently low temperature, dry ice is often preferred over regular ice, which can leave items soggy when it melts. For instance, ice cream that needs to be kept at very low temperatures during transport can be stored with dry ice to maintain its solid consistency.

Cleaning with Precision

Industries are increasingly turning to ice blasting techniques using dry ice pellets. When propelled at high pressure, these ice pellets can remove contaminants and residues from surfaces without leaving any secondary waste, unlike traditional cleaning methods. This technique is popular in fields such as automotive and aerospace for its effectiveness in cleaning without abrasion.

Temperature Control in Chemistry

Within chemical processes, dry ice finds its place in creating controlled reactions. Its capability to keep surroundings at very low temperatures makes it ideal for preserving sensitive materials in laboratories. When dry ice is placed in a well-ventilated environment, it allows for safe gradual sublimation into carbon dioxide gas, facilitating a variety of chemical reactions.

With its ability to transform from a white solid to a gas without turning into liquid, dry ice remains a pivotal element in industries demanding precise cooling solutions. When appropriately used and stored in insulated containers, it ensures efficient results while minimizing risks.

Dry Ice in the Medical Field

Vital Role in Cryogenic Processes

Dry ice plays a crucial role in the medical field, especially within cryogenic processes. Due to its ability to maintain extremely low temperatures, dry ice is essential for preserving temperature-sensitive substances like vaccines, laboratory samples, and certain medications. The solid form of carbon dioxide ensures that these materials remain cold during transportation and storage.Transporting and Storing Temperature-Sensitive Materials

In medical settings, the cold temperatures provided by dry ice make it ideal for shipping delicate medical products across long distances. It is frequently used in an insulated container that helps contain the cold effectively. The white, solid state of dry ice slowly changes back to dioxide gas without entering a liquid phase, making it much more reliable than regular ice.Creating a Sterile Environment

In surgeries and other medical procedures, dry ice can be used to create a cold, sterile environment by blasting the surface with its cold temperature. This process can also aid in the removal of unwanted bacteria or pathogens.Proper Handling Measures

Despite its benefits, handling dry ice requires precautions. It must be stored in a well-ventilated area due to the potential accumulation of carbon dioxide gas. Using the appropriate dry ice handling techniques and protective equipment ensures safety and enhances the effectiveness of its use. For more on effective and efficient solutions for various applications, you might find our ice maker repair services guide helpful.Creative Uses of Dry Ice in Entertainment

Unleashing the Magic of Dry Ice in Entertainment

Dry ice, made from solid carbon dioxide, is a staple in the entertainment industry, adding a touch of magic and mystery to various performances and events. Its ability to transform from a solid to a gas without becoming liquid, a process known as sublimation, creates an enchanting fog effect that captivates audiences.

When dry ice is placed in hot water, it produces a dense, white fog that can fill a room or stage, creating an otherworldly atmosphere. This effect is commonly used in theatrical productions, concerts, and even at themed parties to enhance the visual experience. The fog generated is not only visually appealing but also safe when handled properly in a well-ventilated area.

Beyond fog effects, dry ice is also used to keep food and drinks cold during events. Its low temperature makes it ideal for chilling beverages or preserving ice cream without the mess of regular ice. Additionally, dry ice can be used in ice blasting, a process that involves blasting surfaces with dry ice pellets for cleaning purposes, which can be a part of elaborate stage setups.

While the creative uses of dry ice in entertainment are vast, it's crucial to remember the safety precautions. Handling dry ice requires insulated gloves to prevent skin burns, and it should be stored in an insulated container to maintain its low temperature. Always ensure the area is well ventilated to avoid the buildup of carbon dioxide gas.

Safety Precautions When Handling Dry Ice

Essential Safety Practices for Handling

Handling dry ice safely is crucial due to its very cold temperature and the potential risks associated with its sublimation into carbon dioxide gas. This section outlines key safety measures to follow when dealing with dry ice, whether for industrial applications like ice blasting or creative uses such as fog effects.- Protective Gear: Always wear insulated gloves when handling dry ice. Direct contact can cause severe burns due to its extreme cold nature.

- Well Ventilated Areas: Since dry ice sublimates into carbon dioxide gas, it is essential to use it in a well-ventilated area to avoid breathing complications. Enclosed spaces should be avoided to minimize the risk of asphyxiation.

- Proper Storage: Store dry ice in an insulated container that allows some venting, as gas buildup from sublimation can cause containers to explode under high pressure. Regular ice coolers are often unsuitable due to their tightly sealed nature.

- Handling Precautions: Never place dry ice in sealed glass bottles or containers to prevent dangerous pressure build-ups. Instead, use a container that can handle low temperatures and gas release.

- Avoid Direct Use in Foods: When used in food preparations like ice cream, ensure particles of dry ice have fully sublimated before serving. This prevents the risk of consuming solid dry ice, which can cause internal harm.

- Disposal: To dispose of dry ice, let it sublimate in a well-ventilated space. Avoid using hot water to speed up the process, as this can increase carbon dioxide release, creating fog that may obscure vision and reduce air quality.

Dry Ice and Ice Makers: A Unique Intersection

Innovative Ice Makers and Their Fascination with Dry Ice

Exploring the unique intersection between ice makers and dry ice opens a world of possibilities. While regular ice is common in most ice makers, understanding the integration of dry ice offers fresh prospects in cooling technology. Dry ice, a solid form of carbon dioxide, poses certain benefits, particularly in terms of achieving lower temperatures. In an ice maker, this could allow for quick freezing capabilities, as dry ice has a much lower temperature compared to water-based ice. However, the interaction between dry ice and regular ice involves careful consideration:- Closed Environments: It is crucial to ensure ice makers are well ventilated if using dry ice, to prevent the buildup of carbon dioxide gas, which can increase pressure in closed systems.

- Handling: Handling dry ice requires precautions due to its extremely cold temperature. It should be stored in an insulated container to maintain its solid state.

- Fog Effects: When exposed to air, dry ice will sublimate, turning from a solid to gas, and produce a fog effect, which is sometimes leveraged for visual appeal in various entertainment settings.

-logo-retina.png)