Understanding Common Issues

Identifying the Source of the Problem

- Water Flow Issues: A common culprit when a Hoshizaki ice machine stops making ice is the water supply. Ensure the water inlet valve is open and not obstructed. Check for kinks or disconnects in the water line that could impact water flow into the machine.

- Temperature Concerns: For the ice maker to perform optimally, the temperature must be set correctly. If the ambient temperature or the unit's internal temperature is too high, it may extend the freeze cycle, preventing the ice from forming properly. Make sure the machine is placed in a cool, well-ventilated area.

- Float Switch Malfunction: The float switch controls the water fill level in the ice maker. If it fails, it can cause incorrect water levels or stop the water flow altogether. Inspect the float switch for any damage or necessary adjustments.

- Electrical Component Check: A malfunction in the control board or electrical connections can halt the ice-making process. Confirm all electrical components are securely connected, and search for any signs of damage.

- Beep Alarm Signals: Many commercial ice machines, like the Hoshizaki models, have mechanisms to notify you of issues. A continuous beep alarm could indicate a specific component requiring attention.

- + High capacity: Produces 550 lbs of ice per day

- + Fast production: Ice ready in just 5-15 minutes

- + Large storage: 360 lbs storage bin

- + Durable design: Made with stainless steel

- + Ideal for businesses: Perfect for bars and cafes

Checking the Water Supply

Ensuring Proper Water Flow

To ensure your Hoshizaki ice machine functions efficiently, verifying the water supply is crucial. This step plays a significant role in making sure your ice maker will produce the desired ice without interruptions. Below are the elements you need to consider:- Check the Inlet Valve: The water valve controls the water flow into the ice maker. Examine the valve for any signs of blockages or damage. A faulty water valve can restrict water flow, affecting the ice-making process.

- Inspect Incoming Water Pressure: Adequate water pressure is necessary for the efficient operation of commercial ice machines. Low pressure can prolong the freeze cycle and impede ice production. Consult your unit’s manual for the recommended water pressure levels.

- Evaluate the Water Supply Line: Ensure the water supply line is free from kinks and leaks that may disrupt water flow. Even a slight kink can significantly alter the cycle time for making ice.

- Check the Float Switch: The float switch regulates the amount of water that fills the ice machine bin. If the switch is malfunctioning, it may not shut off the water supply, leading to an overflow or prolonged freeze cycle.

- + High Capacity: Produces 780 LBS of ice per day

- + Quick Production: Makes 234 ice cubes in just 5-15 minutes

- + Large Storage: Comes with a 450 LBS storage bin

- + Durable Material: Made of stainless steel

- + Adjustable Thickness: 22 ice thickness settings for various needs

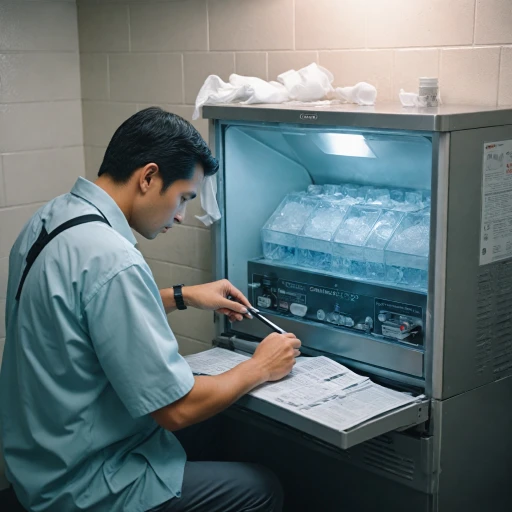

Inspecting the Electrical Components

Examining Electrical Connections and Components

When your Hoshizaki ice machine ceases to make ice, it may be due to an issue with the electrical components. A good place to start troubleshooting is by checking whether the control board is functioning properly. This involves ensuring it's receiving power and not tripping any circuits.

Begin by turning off the machine and unplugging it for safety. Examine the power cord and connections for any signs of damage. Once these components are in good shape, check the control panel for any beep alarms or error codes that might provide insights into the malfunction.

- Float Switch: This part detects water levels and signals the machine to initiate the ice making cycle. Ensure it's not stuck or obstructed. If it's faulty, the machine may not fill with the appropriate amount of water.

- Water Valve: The water inlet valve controls water flow into the machine. A malfunction here can interrupt the water supply, affecting the unit’s ability to fill and cycle through the freeze process.

- Thermostat: The temperature control is crucial. An inaccurate thermostat might misreport the temperature, unduly affecting the freeze cycle of your commercial ice maker.

In addition, verifying connections within the ice maker, such as those linking the bin switch and water inlet, can prevent unnecessary interruptions in service. Be thorough in the inspection of all accessible wires and components to confirm they’re securely attached and undamaged.

Knowing the electrical components of your Hoshizaki ice machine and how to inspect them can address various problems you might encounter. For more insights into optimizing ice production, check out our guide on large ice cubes.

Cleaning and Maintenance Tips

Regular Cleaning for Optimal Performance

Keeping your Hoshizaki ice machine clean is crucial for its performance and longevity. Regular cleaning helps prevent issues like reduced ice production and poor ice quality. Here’s a simple guide to help you maintain your unit:

- Turn Off the Machine: Before starting, ensure the machine is turned off and unplugged. This will prevent any accidents during the cleaning process.

- Empty the Ice Bin: Remove all ice from the bin. This will allow you to clean the bin thoroughly and check for any signs of mold or mildew.

- Clean the Water Inlet and Valve: Check the water inlet and valve for any blockages or mineral build-up. Use a soft brush to gently clean these components, ensuring proper water flow during the ice-making cycle.

- Inspect the Float Switch: The float switch controls the water level in the machine. Make sure it moves freely and is free from debris, as this can affect the freeze cycle.

- Sanitize the Ice Maker: Use a recommended ice machine cleaner to sanitize the interior. Follow the manufacturer’s instructions to ensure all parts are properly cleaned and rinsed.

- Check the Control Board: Inspect the control board for any signs of damage or wear. A malfunctioning control board can disrupt the ice-making process.

- Regular Maintenance Schedule: Establish a regular cleaning and maintenance schedule to prevent future issues. This will help keep your Hoshizaki ice machine running smoothly.

By following these cleaning tips, you can ensure your ice maker remains in top condition, reducing the need for frequent troubleshooting. If you encounter persistent issues, it might be time to consider professional assistance as discussed in the next section.

When to Call a Professional

Engaging Professional Assistance

In some scenarios, enlisting the help of a professional can ensure your Hoshizaki ice machine returns to optimal performance without unnecessary delays or potential complications. Recognizing when it's time to seek expert help can save both time and resources.- Persistent Malfunctions: If the machine continues to experience long freeze cycles or struggles with completing the harvest cycle, a professional technician can conduct a comprehensive diagnostic check. This includes examining complex elements like the control board or float switch that might be affecting the unit's overall functionality.

- Electrical and Technical Issues: Troubleshooting the electrical components such as the power supply or the inlet valve can be challenging and potentially dangerous without proper training. A certified professional will address these aspects safely, ensuring that the machine's operations are restored efficiently.

- Water Flow Irregularities: If previous checks reveal consistent water flow issues, whether from the water inlet or the fill cycle, it's advisable to consult a professional. They can test and replace malfunctioning parts like the water valve, ensuring a smooth water supply to the ice maker.

- Maintenance Services: Routine cleaning and maintenance can extend the lifespan of your commercial ice machine. A professional service can offer thorough cleaning that includes areas that might be difficult to access, such as the ice bin and water supply lines. They will also provide insights into effective preventative measures that can mitigate future issues.

Preventative Measures for Future Issues

Proactive Tips for Smooth Operation

Regular maintenance and preventive measures will ensure that your Hoshizaki ice machine consistently produces ice and operates efficiently. Implementing these practical steps can save you time and prevent common issues from arising.- Regular Cleaning: Cleaning is crucial for maintaining the efficiency of your ice machine. Make sure to follow a consistent cleaning routine to remove mineral build-up, algae, or any other residues that may affect the performance of your unit. Don’t forget to clean the ice bin to ensure safe storage.

- Monitor Water Quality and Supply: Regularly check the water supply line for any obstructions or leaks. Inspect the water inlet and water valve to ensure they are functioning properly. Consider installing a water filtration system to improve water quality and prevent scale build-up.

- Check Electrical Components: Periodically inspect electrical components, such as the control board and float switch, for wear and tear. Ensure connections are secure to prevent interruptions in the ice maker's cycle.

- Evaluate Machine Environment: Ensure your ice machine is in a suitable location with good air circulation. Excessive heat can interfere with its capacity to maintain the correct temperature necessary for optimal ice production.

- Schedule Professional Inspections: Engage a qualified technician to perform routine inspections, which include checking the freeze cycle and harvest cycle. This aids in identifying potential issues early on, saving you from unexpected downtime.