The Role of a Drain Pump in Ice Machines

Understanding the Functionality of a Machine's Lifeline

In the world of ice machines, the role of a drain pump cannot be overstated. These essential components serve as the lifeline for your commercial ice machine, ensuring smooth operation and preventing water overflow. When ice melts or when condensation builds up, the water needs an exit path. A drain pump facilitates this by efficiently moving the excess water or condensation away from the ice machine to a nearest wall or floor drain.

The functionality of ice makers depends heavily on effective draining mechanisms. A gravity drain might suffice for some setups, but many commercial ice makers require the additional power of a drain pump to combat the complexities of varied installation environments. Typically, these pumps are capable of handling significant volumes, with capacities that vary based on need, measured in gallons per hour (gph).

It’s crucial to understand that a pump is not only about moving water; it’s about ensuring operational efficiency and avoiding any potential business disruptions. When looking into shipping options, styles, or price points for these pumps, consider their capacity to handle unforeseen issues, like pump overflow or inadequate draining, which are often signs of a system requiring a drain pump upgrade. For more detailed troubleshooting advice, exploring related resources can also be beneficial, especially in cases where machines suddenly stop making ice. Find more insights here.

Signs Your Ice Machine Needs a Drain Pump

Indicators That Suggest You Need a Helping Hand for Your Ice Machine

Understanding when your ice machine requires a drain pump can be crucial for efficient water management. Here are some signs that your ice machine might benefit from a thorough assessment of its drainage needs:

- Water Overflow: If you notice water pooling around your ice maker, it's a clear indication that a gravity drain is insufficient. A pump can help manage the overflow effectively.

- Evident Condensation: Excessive condensate can lead to floor damage over time. A condensate pump offers an efficient way to channel condensation safely away from the machine.

- Structural Constraints: When your ice maker isn't installed near a convenient floor drain or wall drain, it becomes difficult to rely solely on gravity for draining. In such cases, a drain pump is indispensable.

- Commercial Demands: For businesses and commercial ice machines, especially those with high GPH (gallons per hour) demands, drain pumps ensure the system runs smoothly without interruptions.

Pump ice efficiently by considering the specific needs of your ice maker setup, whether it's for residential or commercial purposes. A good pump can handle the varying demands based on the environment and ice production levels. Remember, the right drain pumps can make maintenance easy and help avoid any disruptions to your business operations.

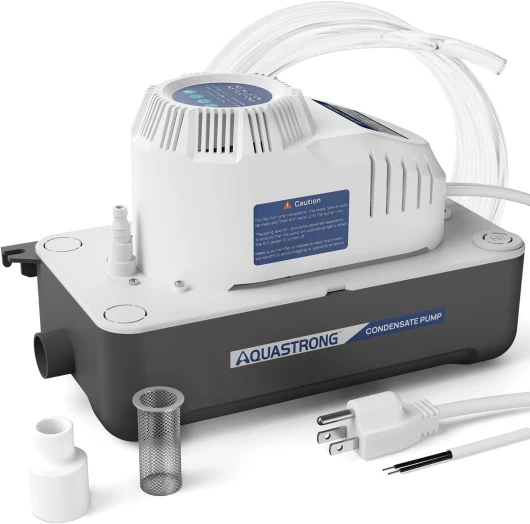

Choosing the Right Drain Pump for Your Ice Maker

Picking the Perfect Pump for Your Ice Needs

When it comes to selecting the right drain pump for your ice maker, there are several factors to consider that can impact both its efficiency and your business's bottom line. Whether you're dealing with a new installation or upgrading an existing system, the right pump is essential to handle condensate and overflow effectively. First, consider the capacity and flow rate of the pump, often denoted in gallons per hour (GPH). If your ice machine produces a significant amount of condensation, choosing a pump with a higher GPH rating ensures that it can efficiently manage the water output. Models with a GPH max allow for handling larger volumes, ensuring smooth operation. Next, assess the type of drainage system in place. Some setups may work better with gravity drains that rely on gravity to move water, while others might require a more robust solution like a condensate pump to lift water to a higher elevation. For locations with a floor drain or wall drain further away, picking a powerful pump is crucial to maintain proper drainage. In commercial settings, price and shipping can also be considerations, especially when dealing with bulk or large-scale operations. It’s advisable to find options that offer a good balance between price and efficiency, as well as reliable shipping services to avoid downtime. Moreover, consider whether you require a system with easy maintenance features. Models that offer straightforward access for cleaning and servicing can save time and extend the lifespan of the pump. This can be particularly important for high-volume commercial ice makers, where machine uptime is critical. Finally, don’t overlook the importance of ensuring that your chosen pump integrates well with your specific machine. Compatibility between the ice machine and pump is crucial for avoiding future issues and ensuring seamless operation. You can explore more about maintaining crystal-clear ice cubes in our crafting crystal-clear ice cubes guide.Installation Tips for Ice Machine Drain Pumps

Ensuring Proper Setup of a Drain Pump for Optimal Performance

Installing a drain pump for your ice machine can seem daunting, but it doesn't have to be. Ensuring the proper setup of your drain pump is crucial for avoiding water-related issues and maximizing the efficiency of your ice maker. Follow these steps to make the installation process seamless:- Identify the Drain Type: Before installation, understand whether your ice machine requires a gravity drain or if a pump is necessary due to the floor level. This is particularly important for commercial ice makers installed where water needs to be pumped to a higher elevation.

- Select the Right Location: Place your drain pump close to the ice machine. Ensure it’s positioned properly to connect easily to your machine drain and that the pump has sufficient gph capacity to handle the maximum output of the ice machine.

- Connect the Drain Lines: Securely attach the condensate pump's intake line to the machine's drain outlet. Make sure the line is free from any blockages that could lead to pump overflow. Flexibility in the pump setup can help accommodate air conditioning units or other condensate sources nearby.

- Secure Electrical Connections: Follow the manufacturer's instructions to connect the pump to a secure power source. It is crucial that your power source offers consistent voltage to avoid fluctuations that might affect performance.

- Testing and Adjustments: After installation, run the ice maker to check for any leaks or operational issues. It may require slight adjustments to ensure the optimal flow of water through floor drains or wall drain outlets.

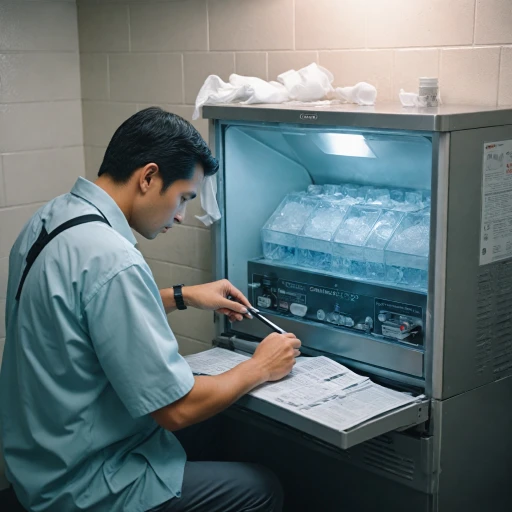

Maintenance Practices for Ice Machine Drain Pumps

Regular Cleaning and Inspection

Maintaining your ice machine drain pump involves regular cleaning and inspection. Over time, debris and mineral deposits can accumulate, affecting the pump's efficiency. To prevent this, schedule routine cleanings. Ensure that the pump and its components, such as the condensate and water lines, are free from blockages. Regular inspections can help identify potential issues early, saving you from costly repairs.

Monitor for Unusual Noises

Unusual noises from your drain pump can be an early sign of trouble. If you notice any strange sounds, it might indicate a blockage or a failing component. Addressing these noises promptly can prevent further damage to your ice maker. Check the pump and surrounding areas for any visible issues, and consult a professional if necessary.

Ensure Proper Ventilation

Proper ventilation is crucial for the efficient operation of your drain pump. Ensure that the area around the pump is free from obstructions. Good airflow helps in managing condensation and prevents overheating, which can lead to pump failure. This is especially important in commercial settings where ice machines are used extensively.

Check for Leaks and Overflow

Regularly check for leaks and overflow around your ice machine and drain pump. Leaks can lead to water damage and affect the pump's performance. Ensure that all connections are secure and that the floor drains are functioning correctly. If you notice any leaks, address them immediately to prevent further issues.

Test Pump Performance

Periodically test the performance of your drain pump. This can be done by observing the water flow and ensuring that the pump is effectively removing water from the ice machine. If the pump is not working at its optimal gph (gallons per hour) capacity, it may need servicing or replacement. Regular testing helps in maintaining the efficiency of your ice maker.

Troubleshooting Common Drain Pump Issues

Addressing Common Ice Machine Drain Pump Problems

Ensuring that your ice machine drain pump functions optimally is crucial for the smooth operation of your ice makers, particularly in commercial settings. Here are steps to troubleshoot some common issues:- Pump Not Activating: If your drain pump is not turning on, check that the machine is properly plugged in and that the power source is active. Inspect the power cord for any visible damage as well.

- Limited or No Water Drainage: When the pump fails to drain water effectively, it could indicate a blockage. Inspect the hoses for obstructions that may prevent water from reaching the floor drains or wall drain effectively. Remember that a gravity drain system relies heavily on clear pathways for water to move freely.

- Overflow Issues: Pumps designed for varying gph max outputs should be appropriately matched to your machine's condensation and water output. An overflow might suggest the condensate pump is not equipped to handle the ice machine’s output or that there's a leak allowing air into the system.

- Noisy Operation: Excessive noise can be a sign of air trapped within the lines or an internal mechanical issue. To address this, check the pump for air leaks and ensure that it’s securely mounted to minimize vibrations that can increase noise levels.

-logo-retina.png)