The Importance of Ice Machine Valves

Understanding the Significance of Ice Maker Components

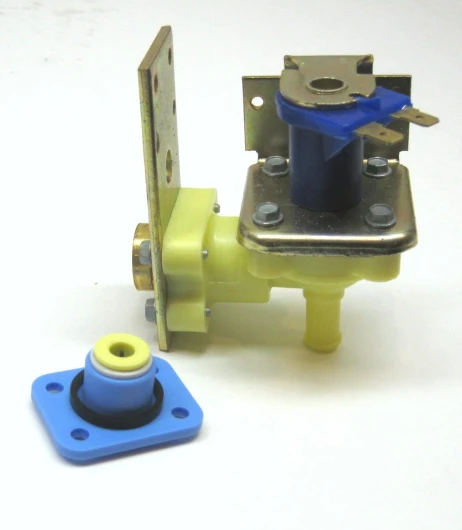

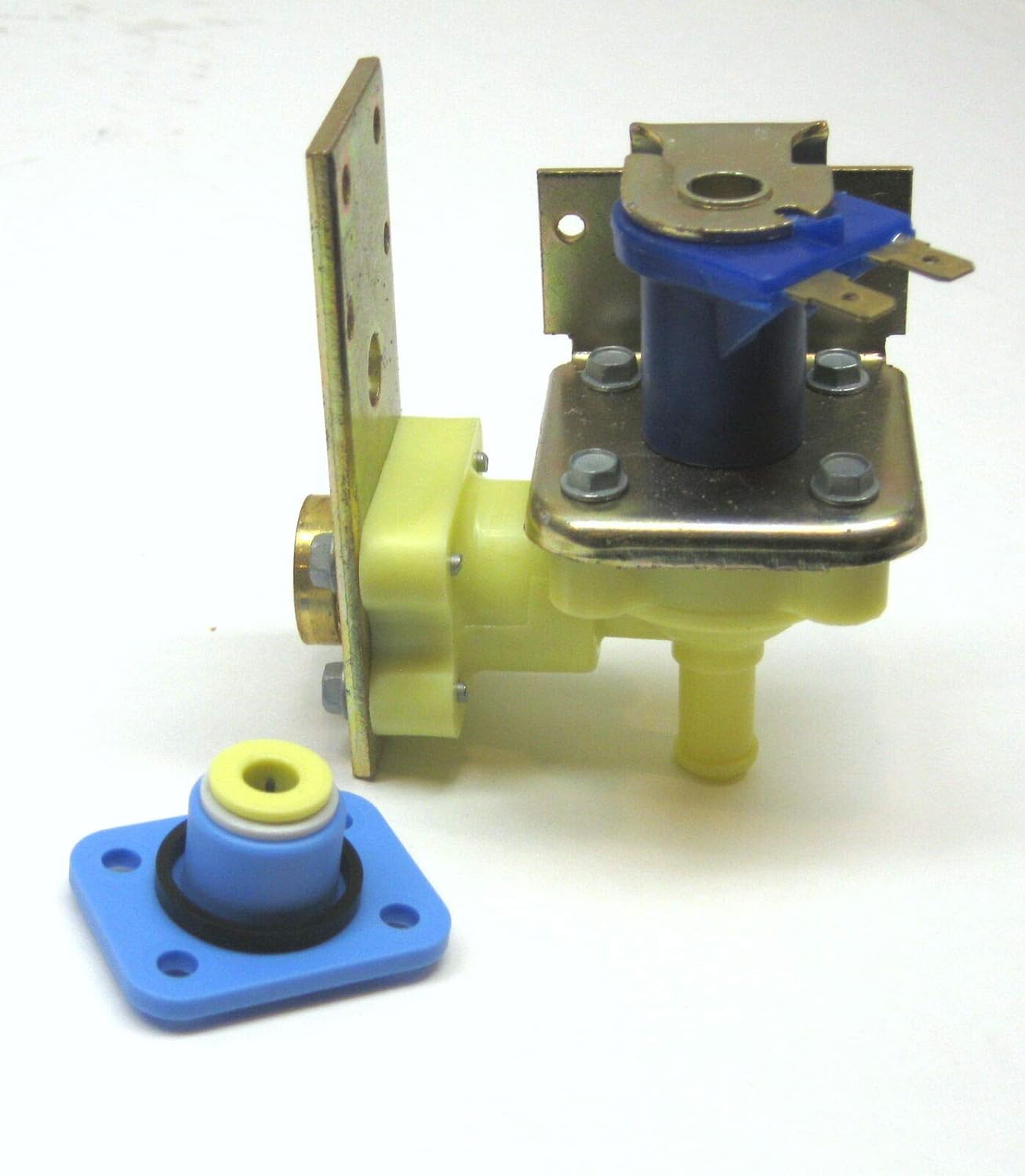

The ice machine valve is an integral part of the entire ice-making process, ensuring that the correct amount of water is delivered to produce ice efficiently. As a crucial component, it helps regulate the flow and control of water, directly affecting the ice maker's performance. Without a properly functioning ice machine valve, you may face disruptions in ice production, inconsistencies in ice quality, and potential machine damage.

For those looking to understand their ice maker better, the troubleshooting guide for common refrigerator ice maker issues is a valuable resource. It can provide further insights into other components that work alongside the valves, such as the solenoid valve and water delivery system. Proper knowledge of these parts will help in identifying any underlying problems efficiently.

The ice machine valve is typically found amongst other vital components like solenoids and water valves. These parts are responsible for managing the amount and pressure of water, ensuring continuous and efficient ice production. Their role extends beyond simple water delivery; they are crucial for maintaining the ideal air balance within the machine, further impacting the quality and clarity of the ice produced.

When considering purchasing an ice maker, it's essential to be aware of the price and shipping options related to replacement parts, including valves. Ensuring a reliable list of product options can prove beneficial when selecting the right ice maker. Regular maintenance of these components will not only lead to a longer life for your ice maker but also guarantee free from potential disruptions.

Furthermore, privacy is a growing concern, and understanding what each item in your ice maker does can help maintain your peace of mind. With an array of featured options available, an educated decision on the necessary parts, including valves, becomes easier and more efficient.

Types of Ice Machine Valves

Understanding Different Valve Types

When it comes to ice makers, choosing the right valve is crucial for ensuring efficient water delivery and ice production. Several types of valves contribute to the functionality of these machines, each with its specific purpose and mechanism.

Solenoid Valves: Solenoid valves are commonly used in ice makers for controlling the flow of water. These electromagnetically operated valves allow precise control over the water entering the machine, making them essential for regulating water supply.

Water Valves: A water valve is integral in managing the water intake, crucial for the ice production process. It's designed to open and close, ensuring the machine receives adequate water without wastage.

Air Valves: Although less common, air valves can assist in regulating the air pressure within the machine, indirectly affecting the performance of water-related components.

Understanding these different valve types can help ice maker product users identify the crucial parts involved and select the best options for replacement or repair. If your ice maker experiences issues, such as inconsistent ice delivery, it might be worth examining these valves. For a detailed guide on troubleshooting your ice maker, consider exploring resources dedicated to these common issues, like this helpful troubleshooting guide.

Common Issues with Ice Machine Valves

Identifying and Resolving Valve Problems

Problems with the ice machine valve can significantly impact the efficiency of your ice maker. Understanding common issues can help you diagnose and resolve them quickly, minimizing downtime and preserving the quality of your water delivery and ice production.- Leakage Issues: One common problem many face pertains to leaking valves. A water valve or solenoid valve that fails to shut completely can result in unwanted water flow, affecting ice quality and potentially causing water damage.

- Solenoid Valve Failures: Solenoid valves are crucial components of many ice makers. When they fail, they can halt the operation entirely. Blockages, wear and tear, or electrical issues often cause solenoid failures, disrupting the machine's ability to produce ice efficiently.

- Air Bubbles in Water Line: Air in the water line can prevent the valve from opening as required, leading to insufficient water flow for ice production. This can cause smaller ice cubes and even contribute to machine jams.

- Incorrect Valve Settings: Sometimes, incorrect settings or adjustments contribute to valve malfunctions. Ensuring that the machine settings are optimized can help prevent unnecessary wear on valve parts.

Maintenance Tips for Ice Machine Valves

Tips for Maintaining Your Ice Machine Valves

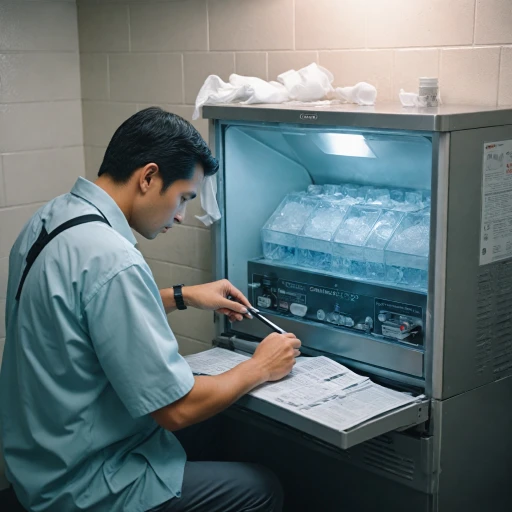

Keeping your ice maker in top-notch condition requires understanding the intricacies of its components, such as the valves. Regular maintenance of these parts is crucial for ensuring efficient operation and prolonging the life of your machine.- Inspect Regularly: Regularly checking the condition of your valves can help you catch wear and tear early. Look for any visible signs of damage, corrosion, or leaks that could affect the water flow or air system.

- Clean to Prevent Build-up: Periodically clean the water valve to remove any mineral deposits or dirt that could restrict water flow. This helps avoid blockages and ensures smooth operation of the product.

- Check the Solenoid Functionality: Ensure the solenoid valve opens and closes properly, as its proper function is critical for water delivery and ice production. Testing the solenoid can prevent any potential disruptions in ice making.

- Keep Spare Parts at Hand: Having spare parts like valves available can help you address any sudden issues without delay, minimizing downtime. This is especially useful given the varying options and features across different ice makers.

- Review Manufacturer's Instructions: Make sure to follow the specific maintenance guidelines provided by the machine's manufacturer. These instructions often include lists of items that need periodic attention, tailored for your particular model.

When to Replace Your Ice Machine Valve

Indications That Your Ice Machine Valve Needs Replacement

Knowing when to replace the valve in your ice maker is crucial to maintaining optimal performance and avoiding further complications. A malfunctioning valve can dramatically impact the ice delivery process, especially if it involves water or solenoid valves.

One major sign that your valve requires replacement is inconsistent ice production. If you've noticed a decrease in the quantity or quality of ice, it's time to inspect the water valve. Irregular water flow can lead to smaller ice cubes or uneven freezing.

Another red flag is unusual noises emanating from the ice machine. Solenoid valves, when worn out, may produce buzzing, clicking, or hissing sounds. If your machine is making unfamiliar sounds, it might be time to check these parts.

Any visible leaks or puddles around the ice maker could imply a faulty valve. A leaking valve can damage other machine components and increase water consumption, affecting your product's performance and price efficiency.

Regular maintenance can help identify these issues early, ensuring your machine operates with featured efficiency. If you're unsure about the situation, consulting a professional might help in deciding whether the valve needs immediate replacement.

Replacing your valve might seem daunting but choosing the right options tailored to your machine's specifications can make a significant difference. Always keep privacy considerations in mind and opt for qualified technicians to handle your ice maker parts and repairs, ensuring you receive free, quality shipping and installation services.

-logo-retina.png)