The Importance of the Water Valve in Ice Machines

Significance of the Water Valve in Ice Production

The water valve plays a crucial role in the operation of an ice machine, acting as the gateway for water supply to reach the machine's internal system. This component is responsible for controlling the water flow into the ice maker, ensuring an adequate supply during each ice-making cycle. Whether you own a Hoshizaki or Scotsman model, the water valve is a vital part that influences efficiency and ice quality. A properly functioning water valve regulates the water pressure and prevents overflow, contributing to the consistent performance of your ice maker. Models equipped with a solenoid valve, such as those found in top brands, offer precise control, enhancing both reliability and ice production consistency. Water valves are available in various types, including the solenoid valve, also known as the inlet valve. These parts can be sourced from a variety of suppliers, including popular online platforms like Amazon, where you can compare prices and delivery options. Selecting the right product for your specific needs is important to maintain optimal ice machine performance, which can even impact how effectively you craft perfectly clear ice at home. Understanding the importance of water valve selections can prevent potential issues caused by incorrect parts or models, often resulting in scenarios where ice machines fail to deliver expected results. In summary, keeping an eye on the water valve’s condition and selecting high-quality options from trusted brands can not only extend the life of your ice maker but also enhance its performance.Common Issues with Ice Machine Water Valves

Typical Problems with Water Valves in Ice Makers

Ice machine water valves, including the inlet solenoid, are crucial parts that often encounter issues that hamper their efficiency. When water doesn't flow into the maker as it should, the culprit could be the water inlet valve. It's essential to keep these parts in check to avoid interruptions in the production of ice. Here's why common problems arise in these components:- Clogged Inlet Filter: Mineral deposits and debris can clog the filters in the water inlet, reducing the flow of water into the machine. This is a frequent issue that affects a range of top brands like Hoshizaki and Scotsman.

- Faulty Solenoid Valve: The solenoid, responsible for opening and closing the valve, can malfunction, leading to water delivery issues. This may result in no water fill, affecting the overall ice output.

- Leaking Water Valve: Wear and tear or damage may cause the valve to leak, resulting in wastage of water and potential damage to other parts of the product.

- Mechanical Failures: Over time, the mechanical elements of the inlet valve can fail due to constant use, which affects the ice production process.

Signs Your Ice Machine Water Valve Needs Attention

Indicators That Suggest Your Ice Maker's Water Valve Requires Your Attention

A well-functioning water valve is crucial for your ice maker to produce ice efficiently. However, knowing when it needs attention can save you from potential issues and costly repairs in the future. Here are some signs to be on the lookout for:

- Inconsistent Ice Production: If your ice machine is producing less ice or the cubes are too small, this could indicate a problem with the water inlet valve. Leaks or blockages in valves can impede the flow of water required for making ice.

- Water Leaks: Finding water pooling underneath or around your appliance might be a serious signal that the valve or any connected parts are malfunctioning. It's crucial to inspect the valve, solenoid, and other related components to ensure there are no leaks.

- Strange Noises: Unusual sounds, like buzzing or hissing, can point to a faulty solenoid valve. This may occur when the valve doesn't open or close properly, preventing the right amount of water from entering the machine.

- Ice Machine Won't Turn On: A malfunctioning valve can prevent your unit from powering on. Since the valve is responsible for water flow, verifying the valve's condition should be one of the first steps in troubleshooting.

Taking the time to recognize these signs can prevent a variety of potential issues with your ice maker. Regular maintenance, paying attention to details like valve positioning, and promptly addressing issues as they arise can help extend the life and efficiency of your machine. Whether you own a popular brand like Hoshizaki or Scotsman, understanding how components like the water valve function will keep your machine in top condition.

Maintenance Tips for Ice Machine Water Valves

Regular Cleaning and Inspection

Maintaining your ice machine's water valve is crucial for optimal performance. Regular cleaning and inspection can prevent many common issues. Start by turning off the ice maker and disconnecting it from the power supply. Carefully remove the water inlet valve and clean it with a mild detergent to remove any mineral buildup or debris. This helps ensure a smooth water flow, which is essential for ice production.

Check for Leaks and Damage

Inspect the valve and surrounding parts for any signs of leaks or damage. Look for cracks or worn-out seals that might affect the water flow. If you notice any issues, it might be time to replace the valve. Remember, a faulty water valve can lead to inefficient ice production or even damage other parts of the ice maker.

Test the Solenoid Functionality

The solenoid valve is a critical component of the water inlet system. Test its functionality by listening for a clicking sound when the ice maker is operating. If the solenoid is not working properly, it might be time to replace it. Brands like Hoshizaki and Scotsman offer reliable solenoid valves that can be found on platforms like Amazon, often with free shipping options.

Schedule Regular Professional Maintenance

While DIY maintenance is important, scheduling regular professional check-ups can help catch issues early. Professionals can provide a thorough inspection and ensure all parts, including the water valve, are in top condition. This proactive approach can save you from high repair costs and extend the lifespan of your ice machine.

Keep an Eye on Replacement Parts

Having a list of replacement parts, such as the water inlet valve, solenoid valve, and other essential components, can be handy. Top brands offer a variety of models, and you can compare prices high and low to find the best deal. Always check the SKU and model number to ensure compatibility with your ice maker.

How to Replace an Ice Machine Water Valve

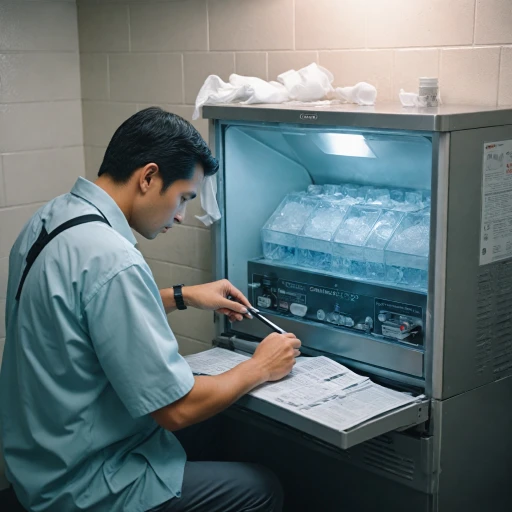

Step-by-Step Guide to Replacing an Ice Machine's Water Valve

Replacing the water valve in your ice machine might seem daunting, but with the right parts and a bit of know-how, it can be a straightforward task. Whether you have a Hoshizaki, Scotsman, or another top brand model, ensuring the proper functioning of the water inlet solenoid valve is crucial for optimal ice production. Here's a guide to help you through the process:

- Identify the Valve: First, consult your ice machine's manual to determine the specific SKU or model number of the water inlet valve you need. Brands like Hoshizaki and Scotsman provide high-quality valves designed for their products.

- Purchase the Right Parts: Once identified, acquire the appropriate valve. Online platforms such as Amazon often offer a wide selection, with various delivery options and price ranges to fit different budgets, from low to high price points.

- Turn Off the Water Supply: Before proceeding with the replacement, ensure that the water supply to the ice maker is fully turned off to prevent any leaks or water damage.

- Detach the Old Valve: Locate the existing water inlet solenoid valve and carefully disconnect it. This usually involves removing screws and disconnecting water lines and electrical connections.

- Install the New Valve: Position the new valve in place. Secure it using the screws and reconnect the water lines and electrical connections. Make sure everything is tightly secured to prevent leaks.

- Test Your Ice Maker: Once installed, turn the water supply back on and power up your ice maker to check for proper operation. Watch for any unusual signs that may indicate issues with the new valve or overall water inlet system.

Regular maintenance can help prevent the need for replacements, but when necessary, following these steps will help ensure a smooth transition and restore the efficient functioning of your ice machine.

Choosing the Right Water Valve for Your Ice Machine

Factors to Consider When Selecting a Water Valve

Choosing the right water valve for your ice machine is crucial to ensure efficient operation and longevity. Here are some key factors to consider:

- Compatibility: Ensure the valve is compatible with your ice maker model. Brands like Hoshizaki and Scotsman have specific requirements, so check the product specifications carefully.

- Type of Valve: There are various types of valves, such as solenoid valves and inlet valves. Each serves a different function, so choose according to your machine's needs.

- Price and Quality: While it's tempting to go for the lowest price, consider the quality and durability of the valve. High-quality parts can save you money in the long run by reducing maintenance and replacement costs.

- Availability: Check if the valve is readily available from suppliers or online platforms like Amazon. Look for options with free shipping to save on delivery costs.

- Brand Reputation: Opt for valves from top brands known for reliability. This can ensure better performance and customer support if needed.

Where to Buy Your Water Valve

When purchasing a water valve, consider both online and local suppliers. Online platforms often provide a wide range of options, allowing you to compare prices and features easily. Look for sellers offering free shipping and check their privacy policy to ensure a secure transaction.

For those who prefer in-person shopping, visiting a local store can provide the advantage of speaking directly with experts who can offer advice tailored to your specific ice maker model.

-logo-retina.png)