Understanding Common Ice Maker Issues

Identifying Common Trouble Spots in Ice Makers

Ice machines, both commercial and home-use, are prone to various issues that may disrupt their functionality. Learning how to spot these typical problems can aid in timely appliance repair and save both time and costs in the long run. Several tell-tale signs indicate that your ice maker might be due for service.

- Insufficient Ice Production: If your ice machine is making less ice than usual, this could be due to factors like a clogged water filter, problems with the water supply line, or mechanical failures. Commercial ice makers, particularly, need consistent and fast production to meet business demands. This common issue requires urgent attention, possibly involving a repair service or a company specializing in refrigeration equipment.

- Ice Quality Degradation: Sometimes the issue isn't the quantity, but the quality of ice being produced. Unpleasant taste, cloudiness, or ice melting too quickly are indicators of underlying problems in your ice maker appliances. The issue might lie in dirty ice maker parts or the need for service support on the air and filtration systems.

- Unusual Noises: Strange sounds emanating from your ice machine can point to mechanical faults. Noise might indicate the need for a range of repairs from air filter changes to adjustments in the refrigeration components of the machine. Contacting a professional for appliance service becomes necessary when DIY troubleshooting tips don't resolve these issues.

Each of these issues necessitates a reliable appliance repair service to diagnose and rectify. For those who encounter depleted ice production or suspect mechanical malfunctions, gaining insights from dedicated resources on troubleshooting ice maker problems can be invaluable in preventing extended downtime of your machine.

Signs Your Ice Maker Needs Repair

Recognizing When Ice Machines Need Repair

Understanding when your ice maker needs repair is crucial in maintaining its efficiency and avoiding prolonged downtime. Here are some key indicators that your ice machine may require professional attention.- Unusual Noises: If your ice maker starts making grinding or rattling sounds, it might signal mechanical issues. Such noises could indicate parts in need of repair or replacement due to wear and tear.

- Insufficient Ice Production: A noticeable drop in ice output often indicates a malfunction. This can be caused by issues such as clogged water lines, faulty components, or problems with the refrigeration system.

- Slow Ice Dispensing: If your ice dispenser is sluggish or stalls, it might be a warning sign of a more significant problem, possibly involving the dispensing mechanism or the ice chute.

- Leaking Water: Water pooling around your ice maker is a serious concern that requires immediate attention. It could be due to leaks in water lines or internal components malfunctioning.

- Ice Quality Issues: If your ice is cloudy, contains unusual odors, or is smaller than usual, it might point to a filtration issue or problems with other parts of the ice maker.

Choosing the Right Repair Service

Finding a Dependable Service Provider

When your ice maker needs attention, identifying a reliable repair service is crucial. With numerous ice machine service companies offering appliance repair, selecting the right one involves careful consideration. Here are some key factors to help you make an informed choice:

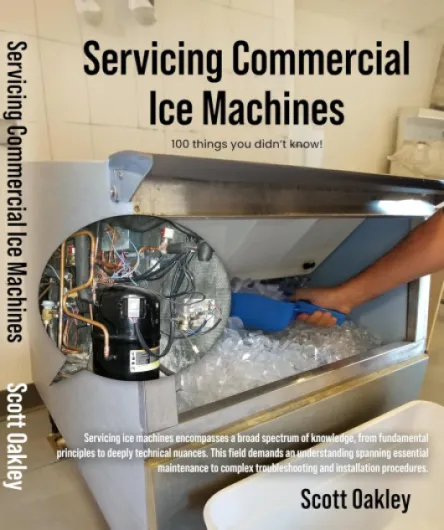

- Experience and Specialization: Look for companies with expertise in repair services for commercial refrigeration equipment. A firm with experience in commercial ice machine repair, including parts and mechanical components, will likely deliver fast, effective solutions.

- Range of Services: Opt for a repair appliance service that provides a range of services, from refrigerator repair to oven repair, and nuggets ice machine assistance. This can be particularly helpful if your appliance needs extend beyond just ice machines.

- Customer Reviews: Reviews from past clients, especially those who had similar issues, can provide insight into the quality and reliability of the company. Positive feedback might underline their capability in providing reliable appliance service and support.

- Response Time: Time is often of the essence, especially for businesses dependent on commercial services. A company that promises swift contact response and prompt handling of repair range requests ensures minimal downtime.

- Service Guarantee: A trustworthy company will back their work with a service guarantee, ensuring peace of mind should any issues arise post-repair.

Ultimately, taking the time to learn more about your ice machine's specific needs and entrusting a professional who understands these appliances can mitigate the need for frequent repairs. Securing a reliable repair service is an investment in keeping your ice maker running smoothly, crucial for both minor household fixes and significant commercial service demands.

DIY Troubleshooting Tips

Explore DIY Troubleshooting Approaches

When your ice maker starts acting up, it's tempting to call a repair service immediately. However, before you go down that route, there are a few troubleshooting steps worth considering.- Power and Electrical Components: Ensure the ice maker is plugged in and check for tripped breakers. Sometimes, issues with ice machines are simple power problems.

- Filter Inspection: Over time, filters can become clogged, impacting the flow of water and ice production. Regularly check and replace filters to maintain optimum performance.

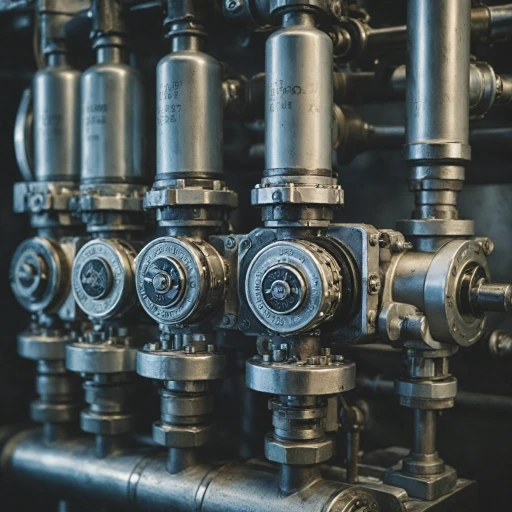

- Valve and Hose Examination: Ice maker hoses can become kinked or pinched, affecting water pressure. Examine hoses and valves for any visible issues or obstructions.

- Ice Jam and Mechanical Parts: Ice can get stuck within the maker or dispenser, hindering its operation. Examine and clear any ice jams, especially in nugget ice machines.

Preventive Maintenance for Ice Makers

Essential Practices to Maintain Your Ice Maker

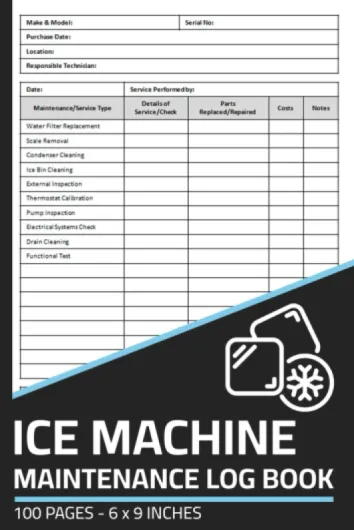

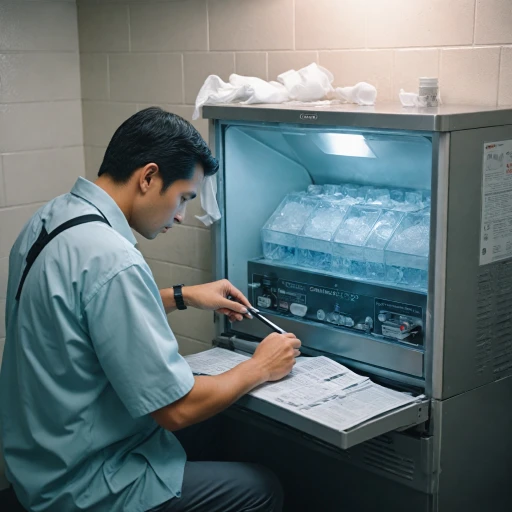

Effective preventive maintenance ensures your ice machine functions optimally, reducing the frequency of repairs and prolonging the lifespan of this vital appliance. Routine maintenance involves cleaning, inspecting, and servicing the ice maker components.- Regular Cleaning Schedule: It’s crucial to clean your ice maker regularly to prevent mineral build-up and bacterial contamination. Depending on usage, consider a thorough cleaning every three to six months using a commercial-grade cleaner specifically designed for ice machines.

- Inspect for Wear and Tear: Regular inspections can help identify potential issues before they escalate. Check the water filter, air filter, and other mechanical parts for signs of wear. Replacing these components in a timely manner can prevent larger problems down the line.

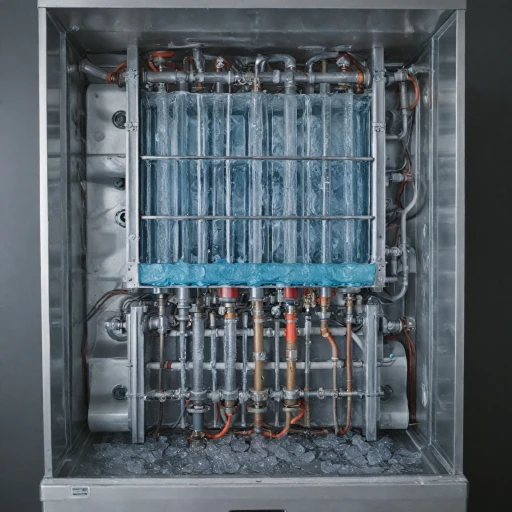

- Check Refrigeration System: Since your ice maker relies on efficient refrigeration to function, ensure that the refrigeration components, including coils and fan, are clean and free of obstructions. Dirty coils lead to reduced efficiency, causing your ice maker appliance to work harder.

- Assess the Water System: A reliable water supply is crucial for ice production. Ensure that the water inlet valve is clean and not blocked. Check for leaks or clogs in the water line that could affect the ice making process.

- Professional Maintenance Services: While you can handle basic maintenance tasks, schedule professional appliance repair services at least once a year. A qualified repair service can conduct a comprehensive review of your ice maker, ensuring everything functions smoothly and efficiently.

Cost Considerations for Ice Machine Repairs

Financial Aspects to Keep in Mind

When dealing with ice maker repairs, it's important to understand the financial aspects involved. The cost considerations can vary widely depending on the type of ice machine you own, the complexity of the issue, and the service fees of the appliance repair company. Here are some factors to consider:

- Extent of the Damage: If the problem affects key parts of the ice machine or is mechanical in nature, expect higher repair bills. Conversely, minor issues like a clogged ice dispenser might be less costly.

- Type of Repair Service: Commercial services and those providing fast, emergency service might have higher rates. Conversely, some appliance repair providers offer more affordable rates for routine service support.

- Brand and Model: Repairs for high-end or commercial ice machines can be more expensive, particularly if specific parts are required. Nugget ice machines and specialized commercial ice makers might also incur higher costs.

- Service Call Fees: Many appliance service companies charge a fee just for assessing your machine. Be sure to inquire about this when you contact repair services for your refrigeration equipment.

To handle costs more effectively, assess if your manufacturer’s warranty or an extended service agreement covers repair range issues like those affecting the ice maker. Additionally, some companies provide refrigerator repair discounts or offer maintenance packages that include air, oven repair, washing machine upkeep, and more for your range of appliances. These can be a cost-effective solution, especially if you have multiple appliances needing attention.

When searching for the right ice maker appliance repair, consider reaching out to local companies for a phone quote. Comparing a few estimates can save you both time and money while ensuring you choose a reputable repair service.