The Role of Fill Tube Heaters

Importance of Regulating Fill Tube Temperature

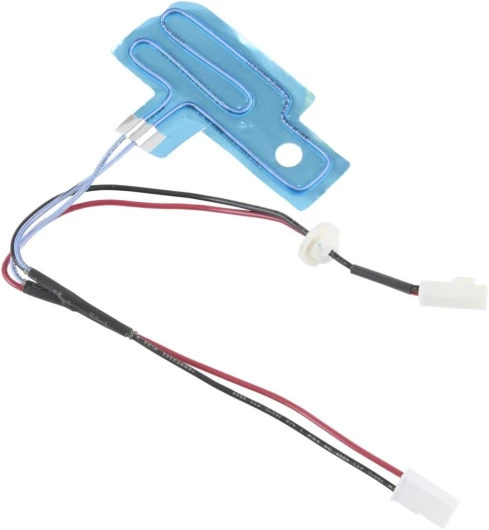

Fill tube heaters play a crucial role in the efficient functioning of your icemaker. These heaters have the primary responsibility of regulating the temperature of the fill tube. By ensuring the fill tube remains free of ice blockages, these heating elements enable a smooth water flow from the water valve into the ice maker.

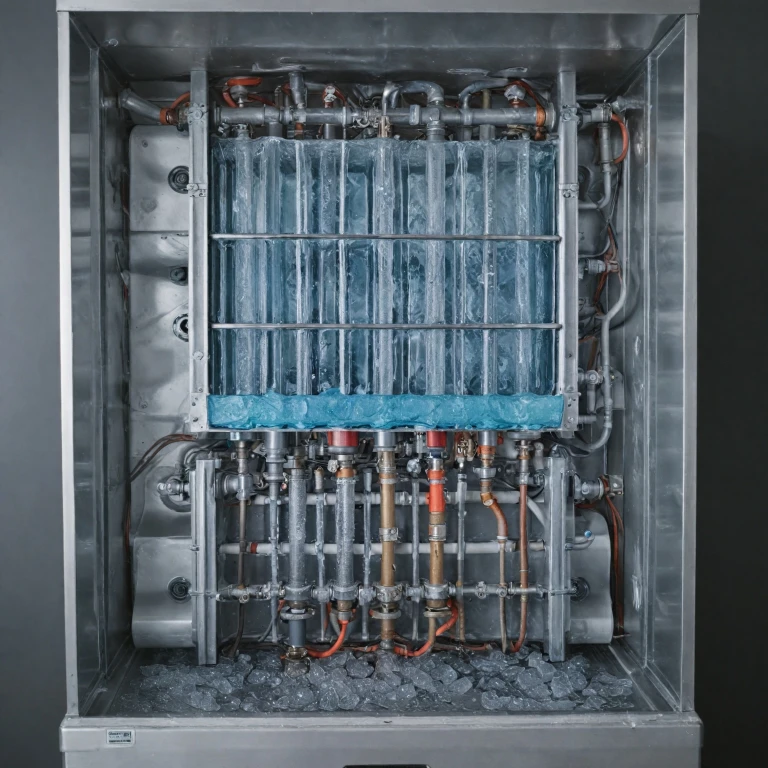

The correct operation of the fill tube heater is vital for the consistent production of ice cubes in your appliance. Without it, the tube could freeze, obstructing water flow and disrupting the ice making process. Regularly checking the fill tube is essential, as it prevents blockages that can lead to reduced ice production or even complete failure.

Advanced models, such as those from Whirlpool and other reputable brands, often include sophisticated components designed to enhance the heating process, ensuring the fill tube efficiently directs water to the ice tray and into the ice bin. Understanding the role of fill tube heaters aids in troubleshooting when something goes awry, such as the icemaker not producing ice. For more guidance on this, refer to troubleshooting ice machine issues.

In summary, a well-functioning fill tube heater is integral to maintaining a seamless transition of water through your refrigerator's icemaker. Proper maintenance and attention to activation triggers ensure that your ice maker will continue to operate optimally over the years, providing fresh ice on demand.

Components Involved in Activation

Key Components That Activate Fill Tube Heaters

Understanding the components involved in activating fill tube heaters is crucial for maintaining your icemaker's efficiency. These components work together to ensure that the ice maker functions smoothly, preventing issues like frozen tubes or water flow disruptions.

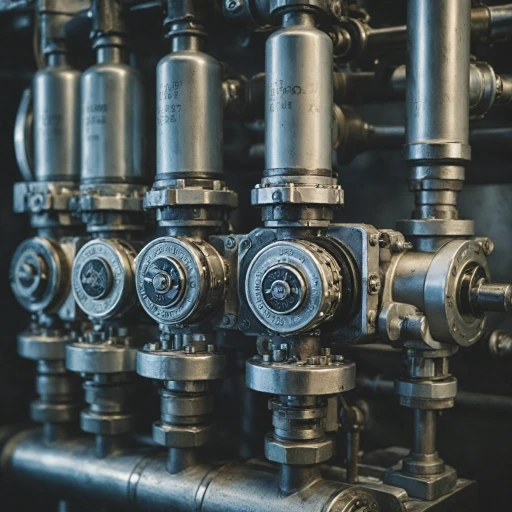

- Water Valve: The water valve plays a pivotal role in controlling the flow of water into the icemaker. It opens and closes to allow water to fill the ice tray, and its proper functioning is essential for the activation of the fill tube heater.

- Control Panel: The control panel manages the overall operation of the icemaker, including the activation of the fill tube heater. It ensures that the heater is activated at the right time to prevent freezing in the fill tube.

- Thermostat: The thermostat monitors the temperature within the freezer and signals the control panel to activate the fill tube heater when necessary. This prevents the water in the tube from freezing, ensuring a steady flow of water.

- Heating Element: The heating element is directly responsible for warming the fill tube. When activated, it prevents ice blockages by maintaining a temperature that keeps the water flowing smoothly.

- Shut Arm: The shut arm detects when the ice bin is full and signals the control panel to stop ice production. This component indirectly affects the activation of the fill tube heater by controlling the overall ice-making process.

Each of these components must function correctly to ensure that the fill tube heater activates as needed. Regular maintenance and troubleshooting can help address any issues that arise, keeping your ice maker in top condition. For more detailed troubleshooting tips, you can explore troubleshooting when your Hoshizaki ice machine stops making ice.

- + Fast Ice Production: 9 bullet ice cubes in just 6 minutes

- + Self-Cleaning Function: Easy maintenance

- + Portable: Ideal for home, kitchen, RV, and camping

- + Compact Design: Saves space on countertop

- + Quiet Operation: Doesn't disturb your environment

Common Triggers for Activation

Understanding Activation Triggers

Activating the fill tube heaters in a refrigerator icemaker involves several factors and common conditions that need to be identified. Understanding these key triggers not only aids in maintaining the icemaker's efficiency but also prevents issues arising from improper activation.- Temperature Fluctuations: The significant temperature shifts within the freezer impact the function of the fill tube. As temperatures drop, the fill tube becomes susceptible to freezing, which necessitates the activation of its heating element to maintain a consistent ice-making process.

- Water Flow Interruptions: The water valve plays a pivotal role in ensuring a steady flow of water into the ice maker fill tube. If there's an interruption in the water flow, be it from a blocked water filter or a malfunctioning arm, it can complicate the activation of these heaters.

- Sensor Responses: Modern icemakers, such as those found in Whirlpool appliances, come equipped with sensors and a control panel that monitor the water levels and ice storage. These sensors trigger the fill tube heaters to turn on or off based on specific water and ice conditions.

- Increased Ice Production Demand: In scenarios where the demand for ice spikes, such as during a social event, the refrigerator icemaker might increase production. In these cases, the fill tube heaters are more frequently activated to ensure that ice cubes are efficiently produced and transferred from the ice tray to the storage bin.

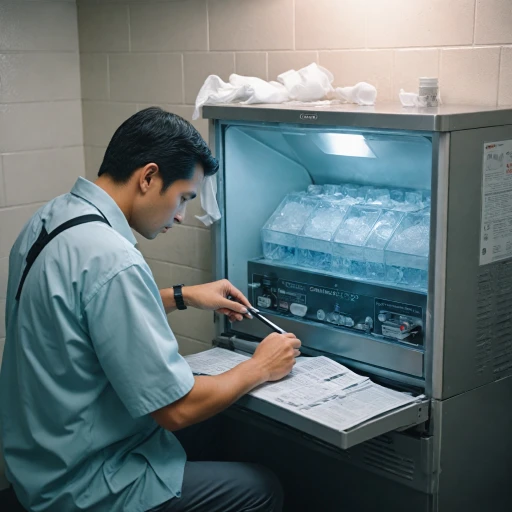

Troubleshooting Activation Issues

Tackling Fill Tube Heater Activation Problems

When the fill tube heaters of your icemaker cease to operate correctly, it can disrupt the entire ice making process. This section will delve into common problems and solutions to restore functionality.- Check the Control Panel: The control panel governs the activation of heating elements. If it malfunctions, the heaters may not activate, leading to a frozen fill tube. Ensure that the control panel is set correctly and that no errors are evident in the display.

- Examine the Water Valve: If your icemaker is not getting a steady supply of water, the heater may not activate. Inspect the water valve for blockages or damage. A failure in the valve could prevent water from reaching the fill tube.

- Inspect the Shut Arm: The shut arm halts ice making when the ice bin is full. If it's stuck or broken, it can prevent the activation of the heater. Verify that the arm is moving freely and in its correct position.

- Evaluate Electrical Connections: Loose or corroded connections can impede electrical supply to the heater. Check for signs of wear and securely fasten any loose wires connected to the refrigerator icemaker's components.

- Test the Heating Element: A defective heating element means no ice. Test the continuity of the element with a multimeter. If it lacks continuity, a replacement may be necessary.

- Review the Tube Water Path: Over time, deposits can form in the fill tube due to mineral buildup in the water. This could obstruct flow and impact heater activation. Cleaning the tube and replacing the water filter regularly will help maintain efficiency.

Maintenance Tips for Optimal Performance

Maintaining Optimal Icemaker Heater Functionality

To keep your icemaker performing efficiently, regular maintenance is crucial. Here are some tips to ensure the fill tube heaters in your refrigerator icemaker continue functioning optimally.- Inspect the Water Filter Regularly: Replace the water filter every couple of weeks or as recommended by your refrigerator manufacturer. A clean filter ensures that water flows correctly through the fill tube, reducing the chances of blockages and inefficient ice making.

- Check the Water Supply: Regularly examine the water valve and tube water connections to ensure there are no leaks or obstructions that could affect the flow of water through the icemaker's fill tube.

- Clean the Ice Bin and Ice Tray: Ensure the ice bin and ice tray are free from any ice build-up or debris. This prevents the ice from forming incorrectly and keeps the icemaker's shut arm from malfunctioning.

- Monitor the Control Panel Settings: Make sure your control panel settings are set to the appropriate levels for making ice. Incorrect settings can interfere with the operation of the heating element, affecting the performance of the icemaker fill system.

- Regularly Test the Heating Element: Check the heating element to ensure it's functioning correctly. Signs of a faulty heating element include ice build-up on the fill tube and inconsistent ice cube production.

- Examine Valve and Arm Functionality: Regularly test the water valve and shut arm to guarantee they are operating correctly, helping to maintain a smooth water flow into the ice maker fill tube.