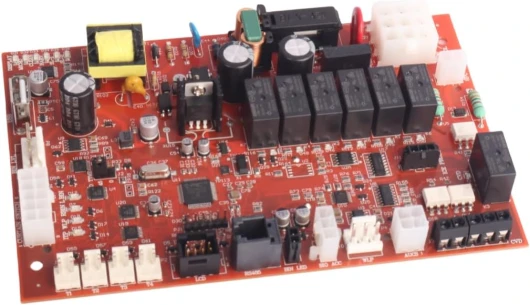

The Role of the Ice Level Control Board

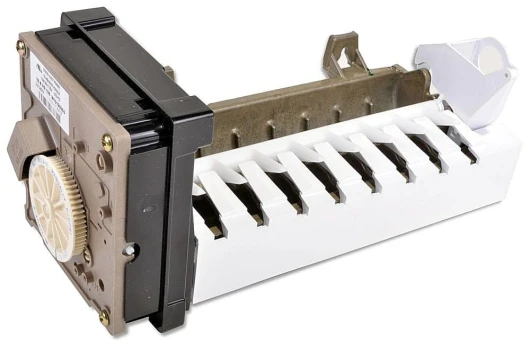

Key Component in Ice Making Process

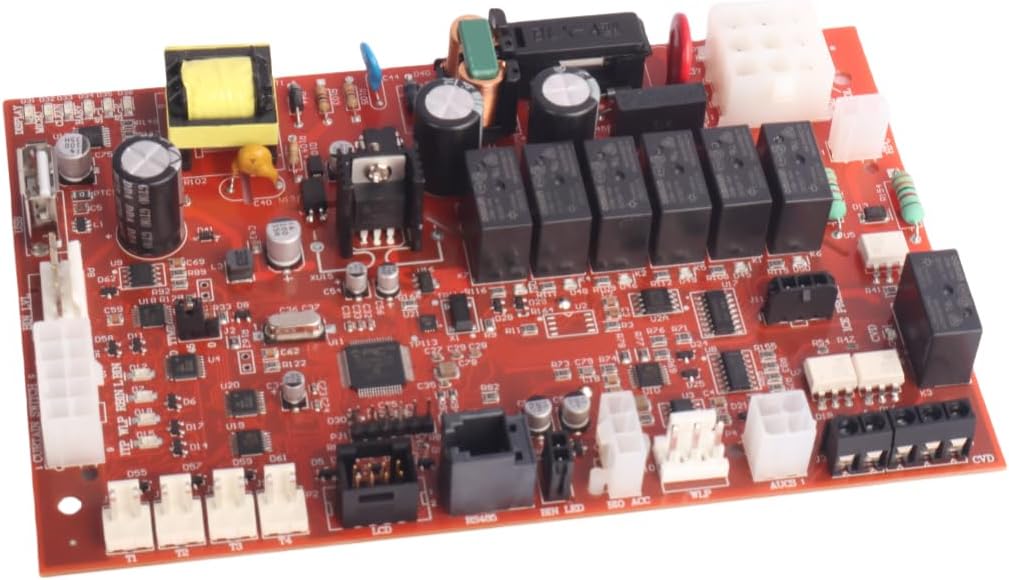

The ice level control board plays a crucial role in the functioning of your Whirlpool ice maker. As part of the refrigerator's system, this component is responsible for regulating the ice production process, ensuring that your fridge and freezer work together seamlessly to deliver a consistent supply of ice. It coordinates with other critical parts like the emitter board and receiver board, forming a comprehensive maker assembly that allows your ice maker to perform optimally.Monitoring Ice Production Levels

One of the primary functions of the control board is to monitor the ice level in the maker ice storage bin. When the ice level reaches a predetermined threshold, the board sends a signal to halt production, preventing an overflow. Conversely, when the ice level drops, it signals the ice maker to resume production. This regulation ensures the right ice amount is always on hand based on your usage.Ensuring Timely Ice Ejection

In addition to monitoring ice quantities, the control board also supports the timely ejection of ice into the storage bin. It collaborates with the freezer door mechanisms to ensure that ice production continues regardless of normal opening and closing activities. By overseeing this process, the board contributes to a more efficient ice maker performance, reducing waste and maintaining energy efficiency. For those experiencing issues with their ice level control board, troubleshooting might be necessary to diagnose specific problems affecting ice production. Explore troubleshooting tips for a malfunctioning Kenmore ice maker for insights that could apply to different brands, including Whirlpool. Understanding common issues with control boards can also help you make informed decisions on whether to replace or repair components, ensuring your refrigerator's ice maker works great.Common Issues with Ice Level Control Boards

Potential Problems with the Control Board System

Sometimes, issues arise with the ice level control board in your Whirlpool refrigerator, affecting the ice maker's performance. Identifying these common problems can help in addressing them effectively.- No Ice Production: If your ice maker isn't producing ice, the control board might not be sending signals to start the making ice process. It's important to check if the emitter and receiver boards are properly aligned and functioning.

- Erratic Ice Production: Inconsistent ice levels may indicate that the board needs calibration or a potential parts issue. Ensure that the sensor on the control board isn't obstructed by any build-up.

- Ice Overproduction: When the ice maker doesn't stop after the bin is full, the level control board could be failing to respond to the feedback from the optic board.

- Ice Blockage: An improperly defrosted fridge can cause water to freeze in unwanted places, disrupting the board's ability to work correctly. This might require you to defrost the freezer or verify that the door seals properly to avoid condensation issues.

Troubleshooting Ice Level Control Board Problems

Identifying Problems and Finding Solutions

Troubleshooting the ice level control board in your Whirlpool ice maker involves understanding the various problems that can occur. If your ice maker isn't functioning as expected, there are several things you can check and do before jumping to conclusions or seeking professional help.- Check the Optic Board: The optic board, comprising the emitter and the receiver boards, plays a critical role in regulating the ice level. If the optic board isn’t working properly, it can lead to freezing issues or the ice maker not making ice at all.

- Inspecting the Control Board: The control board in both your fridge and freezer is vital. If the control boards are faulty, it may affect the entire ice-making process. It’s often a good idea to inspect the board set to ensure all connections are secure and there are no visible damage or burns.

- Check the Water Supply: Make sure the water line to the ice maker is functional. Issues with water delivery can halt ice production. For a more detailed guide on the importance of the water inlet valve in your ice machine, click here.

- Testing the Ice Level Control: After confirming the physical condition of the control board and the water supply, test the ice level sensors. These sensors ensure the maker ice doesn't overflow. A quick test can verify if the sensors are correctly sensing the ice level.

- Defrosting the Freezer: Sometimes a build-up of frost around the control board or sensors can cause malfunction. Make sure your refrigerator’s defrost cycle is running smoothly to prevent this.

Maintenance Tips for Optimal Performance

Ensuring Your Ice Level Control System Stays in Peak Condition

To keep your Whirlpool ice maker's control board functioning optimally, regular maintenance is key. The level control system, comprising several crucial parts such as the optic board and the emitter board, requires attention to ensure that everything works great.- Regular Cleaning: Dust and debris in the refrigerator and freezer can affect the optic board and other components. It’s essential to keep the area around your ice maker clean to prevent blockages that may hinder performance.

- Check Connections: Loose or corroded connections can interrupt the maker ice production. Periodically check the connections on the board set, especially the maker control connection near the refrigerator door, for any signs of wear or damage.

- Inspect the Optic and Emitter Boards: The optic board and emitter board are integral to monitoring the ice level. If your ice level control isn’t working correctly, visually inspecting these boards for any damage or obstructions is a good practice.

- Defrost the Freezer Regularly: Regular defrosting prevents ice buildup that can interfere with the sensor. By doing so, you help the entire ice assembly, including the control boards, to function properly.

When to Seek Professional Help

Identifying the Need for Expert Assistance

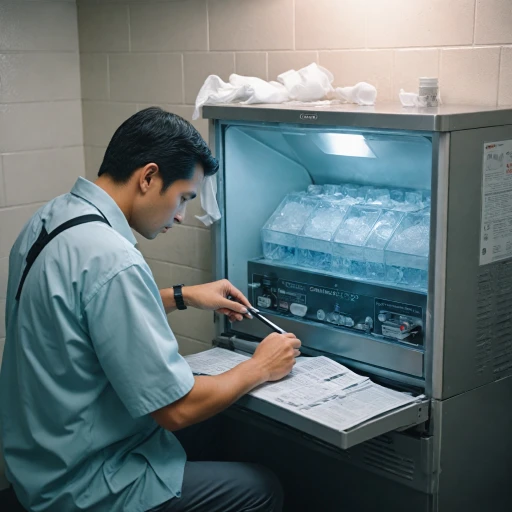

While routine maintenance and basic troubleshooting can resolve many issues with your ice-making system, there are times when it’s best to call in a professional. Recognizing when this is necessary can prevent further damage and ensure that your Whirlpool ice maker functions efficiently. Here are some scenarios where expert intervention could be vital:

- Persistent Malfunctions: If the ice level control board continues to malfunction despite following troubleshooting steps, professional help is advised. This could involve intricate issues within the control boards not immediately evident without specialized tools.

- Electrical Problems: Wiring complications within the refrigerator ice systems should be handled by a certified technician. Tinkering with electrical components, such as the emitter board or receiver board, could lead to hazards or void warranties.

- Complex Diagnostic Needs: When the maker control or optic board requires specialized diagnostics, an expert can efficiently pinpoint issues, ensuring parts are exactly needed and replaced.

- Warranty Concerns: Engaging a professional might be crucial if your appliance is under warranty. Unauthorized repairs might not be covered, emphasizing the importance of a certified check.

Professional technicians from the brand Whirlpool or an authorized service provider will have a deeper understanding of how each component, like the level control or board set, functions within the entire system. Their expertise ensures your fridge and freezer continue to add to your good experience, maintaining a steady stream of ice while protecting your significant investment.

Choosing the Right Replacement Parts

Finding the Right Replacement Parts for Your Whirlpool Ice Maker

When your Whirlpool ice level control board experiences issues, finding the appropriate replacement parts becomes essential to restore optimal functionality. Here's a guide to help you make a wise purchase for your refrigerator ice system.- Identify the Exact Parts Needed: Before purchasing, ensure you know exactly what's required for your ice maker repair. Different models might use specific control boards, such as the emitter board, optic board, or receiver board. Understanding the specific board set part number for your fridge will lead to an accurate replacement.

- Check Compatibility with Your Whirlpool Model: Whirlpool refrigerators and freezers come equipped with a variety of control boards. Verifying the compatibility of a replacement part with the existing make and model of your fridge will ensure the parts work great together. This can be cross-referenced with the refrigerator’s user manual or online databases provided by the brand.

- Consider Quality and Brand Reputation: Opt for parts from a reputable brand or supplier. Getting control boards from well-known brands increases the likelihood they will function effectively within your ice maker assembly. This also ensures durability and reduces the need for frequent replacements, saving you time and effort in the long run.

- Seek Professional Guidance if Needed: While choosing the right part, consulting with an appliance repair professional can be valuable. They can provide insights on whether it's necessary to replace the entire ice making system or just a specific component.

- Purchase from Authorized Dealers: To guarantee that you’re acquiring genuine and good-quality parts, always purchase from authorized dealers or directly from the Whirlpool website. Avoiding third-party sellers ensures product authenticity and can help prevent operational problems in the future.

-logo-retina.png)