Understanding Bulk Ice Production

Exploring the Dynamics of Efficient Ice Production

Understanding bulk ice production is critical for businesses and events that require large quantities of ice, whether it's delivering emergency supplies or fulfilling daily customer needs. Companies specializing in ice supply provide various forms of ice to suit different requirements. Products like bagged ice, block ice, and even dry ice are tailored for specific uses, from keeping products cold to preparing for special events. A successful bulk ice operation starts with awareness of the specific ice types and quantities needed. For instance, packaged ice like Arctic Glacier and Reddy Ice are often sold by the bag or pallet, with each offering different benefits in terms of size, texture, and cooling efficiency. Customers may order ice in varying formats—from glacier-clear cubes to mobile ice services for events—ensuring that delivery meets their precise demands. Efficient ice production also depends on optimizing your supply chain. Regular orders and delivery ice services support continuous operations, preventing disruptions during high-demand periods like special events or emergencies. Premium services may include same-day delivery or specialized customer service to handle urgent requests efficiently. To excel in bulk ice production, it's essential to consider factors such as price and overall quality of the ice products. Click here to explore more about the art of crafting the perfect ice, ensuring your offerings meet the highest standards of clarity and performance.

- + High Production Capacity: Produces 450 lbs of ice per day

- + Quick Ice Making: Ice ready in 8-15 minutes

- + Large Storage: Holds up to 120 lbs of ice

- + Versatile Use: Suitable for restaurants, bars, cafes, and businesses

- + Under Counter Design: Space-saving installation

Choosing the Right Ice Maker for Bulk Needs

Key Considerations for Selecting an Ice Maker

When choosing the right ice maker for your bulk ice production needs, it’s essential to evaluate several factors to ensure efficiency and satisfaction. Understanding your specific requirements, including the volume of ice needed and the events you cater to, will significantly shape your decision.

- Ice Types and Volume: Consider the type of ice you need, whether it’s cubes, flakes, or block ice. Whether you are planning for a premium event or handling day-to-day customer demands, your ice maker should match your volume needs, often measured in pounds.

- Cost and Energy Efficiency: Balancing the price of the ice maker and its ongoing operating costs is vital. Look for models that offer energy-efficient features to help reduce long-term expenses.

- Delivery and Storage Capabilities: Assess the ice maker's ability to support your delivery ice services. This includes evaluating its compatibility with mobile ice solutions or its capacity to produce bagged or palletized ice for storage and transportation.

- Emergency and Special Event Readiness: Ensure the ice maker can handle surges in demand during special events or emergency ice needs. Investing in a reliable machine can prevent potential service disruptions for your customers and enhance customer service outcomes.

Considering the varying ice needs, from regular use to special events planning, an informed choice ensures seamless operation. For a creative twist on utilizing your ice production, explore some fun ways to make Nutella ice cream using your ice products.

Choose your ice maker wisely, whether you’re delivering ice to major events or ensuring your customers receive the highest quality bagged ice. With these considerations, you’ll be well-prepared to meet the demands of any situation, be it an arctic glacier-like requirement or the reliable consistency of day-to-day ice delivery services.

Installation and Maintenance Tips

Installation Best Practices for Bulk Ice Makers

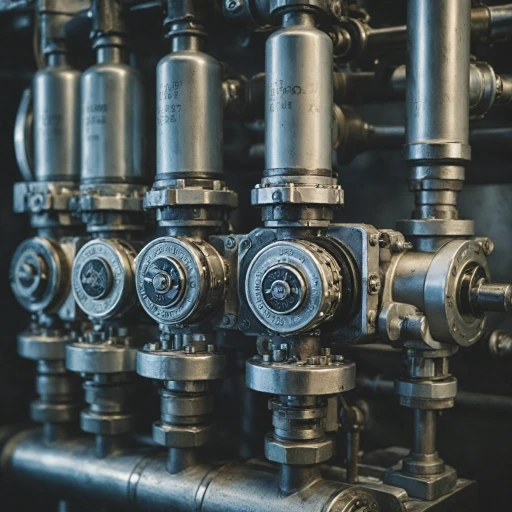

Installation of an ice maker designed for bulk production involves several key factors that will ensure optimal performance. Begin by assessing the space available, ensuring there is ample room for proper ventilation and access to services such as water and electrical connections. Proper installation is crucial as it helps in maximizing the output and longevity of the machine, reducing disruptions in ice delivery during peak demand periods.

Routine Maintenance Guidelines

Regular maintenance is vital to avoiding service disruptions and extending the life of your ice maker. It's advisable to establish a maintenance schedule that includes cleaning and checking for any signs of wear and tear. Maintenance includes removing scale build-up, cleaning water filters, and checking the temperature settings. Blockages can lead to reduced efficiency, impacting the availability of ice for delivery and special events, so handle them promptly. Engaging with the manufacturer for customer service and support when needed can also prove beneficial.

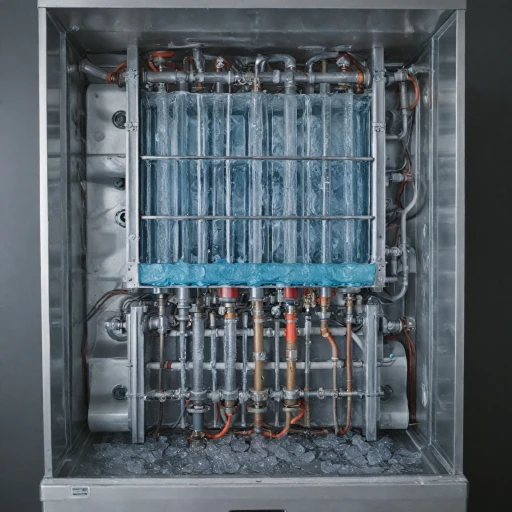

Ensuring Component Efficiency

To maintain high efficiency, ensure that all components are functioning as intended. Regularly check the evaporator coils, fans, and any moving parts to prevent unexpected breakdowns that could delay deliveries or impact your reputation for reliability during emergency ice needs. Timely inspection and replacement of components like water filters can significantly enhance the quality of ice, balancing the cost with the premium experience expected by customers.

Energy Efficiency and Cost Considerations

Boosting Energy Efficiency and Reducing Costs

Efficiency is key when running a bulk ice production operation. Opting for energy-efficient ice makers not only meets your ice needs but also significantly cuts down on energy expenses. Investing in machines known for their reduced energy usage ensures that both operational costs and environmental impact are minimized. A critical consideration involves selecting energy-efficient models designed for bulk production—machines capable of generating significant quantities of ice while maintaining energy economy. Evaluate products based on their energy consumption rates and search for ENERGY STAR certified options, which often represent the benchmark in energy-efficient ice-making technology.Lowering Costs with Smart Practices

Efficient installation and routine maintenance can help optimize energy use. Regular servicing helps to avoid unexpected equipment failures and need for emergency ice services, preventing involuntary downtime and costly repairs. Staying proactive ensures your ice maker operates at peak efficiency, providing reliable delivery ice for daily operations and special events. Consider the long-term order and cost benefits of purchasing higher quality ice makers—premium products generally offer improved durability and efficiency, ultimately saving money over time. Take the time to weigh the price against performance metrics, specifically focusing on energy usage and production capabilities.Maximizing Savings Through Innovations

Staying informed about the latest advancements in ice maker technologies, such as those capable of utilizing renewable energy sources, can drive efficiencies up and costs down. Leverage innovations to meet the demands of high-volume environments, such as events requiring bulk delivery of products or matters concerning emergency ice. New advancements often lead to increased lbs of ice produced with less energy, making them worthwhile investments. Don’t forget that reputable ice suppliers bring valuable insights and customer service experiences to the table. These customers can recommend best practices and offer product advice, ensuring you never run short of ice, whether it's for bagged ice packs, glacier-inspired cubes, or special event needs.

- + High Production Rate: Makes up to 101 lbs of ice per day

- + Large Storage Capacity: 33 lbs of ice storage

- + Fast Ice Production: 45 ice cubes in just 12 minutes

- + Self-Cleaning Feature: Automatic cleaning cycle

- + User-Friendly: LED digital display for easy operation

Common Challenges in Bulk Ice Production

Overcoming Obstacles in Large-Scale Ice Production

Producing ice in bulk can be a challenging endeavor, especially when aiming to meet the demands of special events or regular customer orders. One of the primary challenges is ensuring a consistent supply of ice, whether it's cubes, blocks, or bagged ice. This is crucial for businesses like mobile ice services or those dealing with emergency ice delivery.

Another common issue is managing the logistics of ice delivery. Coordinating the delivery of large quantities, such as ice pallets or pounds of ice, requires efficient planning and reliable transportation. This is particularly important for ice suppliers who need to maintain a high level of customer service.

Price fluctuations in the market can also pose a challenge. The cost of ice products can vary, impacting the overall pricing strategy for businesses. It's essential to keep an eye on market trends to offer competitive prices without compromising on quality.

Maintenance of ice makers is another critical aspect. Regular upkeep is necessary to prevent breakdowns, which can lead to delays in ice production and delivery. Ensuring that your equipment is in top condition helps avoid emergency situations where ice is needed urgently.

Finally, adapting to innovations in ice maker technology can be daunting but necessary. New advancements can improve efficiency and reduce costs, but they require an initial investment and training. Staying updated with the latest technology ensures that your ice production remains competitive and efficient.

Innovations in Ice Maker Technology

Emerging Trends in Ice Maker Technology

The evolution of ice maker technology has significantly impacted the overall efficiency and functionality of bulk ice production. Manufacturers have consistently pushed the boundaries, leading to innovations that cater to diverse customer needs. Whether it's bagged ice for special events or mobile ice delivery services, these advancements in technology are worth noting.

One notable trend is the integration of smart technology in ice makers. With smart controls, users can easily monitor and adjust their ice production systems remotely via mobile devices. This allows businesses to respond swiftly to demands, whether during emergencies or regular operations. The efficiency gained reduces the cost and time often associated with manual adjustments.

Another trend is the development of rapid freezing technologies. These systems expedite the freezing process, ensuring that ice is produced quicker, which is crucial during peak demands, such as special events or emergency situations. Moreover, such technologies improve the quality of ice, producing clear, high-quality cubes suitable for premium applications.

Environmentally friendly innovations are also gaining traction. The focus on reducing energy consumption and water waste aligns with the global push for sustainability. Modern ice makers are built with energy efficiency in mind, translating to lower operational costs and an eco-friendly business model. Furthermore, innovations in cooling mechanisms lessen the environmental footprint while maintaining consistent ice temperature and quality.

The rise of versatile products also merits attention. Ice makers capable of producing different types of ice, such as block ice, dry ice, or Arctic glacier cubes, provide businesses the flexibility to meet varied customer demands. Such adaptability is advantageous for suppliers serving a wide range of industries, from food services to medical applications.

As new technologies emerge, the landscape of ice production continues to transform. These innovations not only enhance operational efficiency but also ensure customer satisfaction by providing high-quality ice at competitive prices. Staying abreast of these advancements is essential for anyone involved in the industry, whether they're ordering pounds of ice for events or managing day-to-day ice delivery services.

-logo-retina.png)